Building a better artificial knee

Binghamton researcher's sensor could enable joint implant to “talk” to doctors

The more we embrace “smart” technology, the more time we spend recharging phones, fitness trackers, robot vacuums and no end of other devices. So, what happens when smart surgical implants become the norm? How will we keep them charged without, say, hooking our bodies to power adapters?

Shahrzad (Sherry) Towfighian might have a workable solution.

An associate professor of mechanical engineering, Towfighian was lead investigator on a recent study to demonstrate a smart knee replacement that requires no batteries or external power source. The device uses friction from the motion of the artificial knee to generate current that powers the electronics.

Towfighian and her collaborators — Emre Salman of Stony Brook University and Ryan Willing of Western University in London, Ont. — did their work with support from a two-year, $349,104 grant from the National Institute of Arthritis and Musculoskeletal and Skin Diseases of the National Institutes of Health (NIH).

The project started with a conversation between Towfighian and Willing, who was then a colleague in mechanical engineering at Binghamton. Willing was studying knee implants. Towfighian was working on energy harvesters that convert mechanical energy to electrical energy and could act as sensors.

“I asked, ‘How about if we put a sensor in the knee implant?’” Towfighian says.

The sensor would measure the load that a patient’s activity — walking, running, dancing, etc. — exerted on the artificial knee. This is an important thing to track, as many younger, moreactive patients are now opting for knee replacements. A study presented at the 2014 meeting of the American Academy of Orthopaedic Surgeons found that the number of such surgeries among 45- to 64-year-olds had climbed by 188 percent in the previous 10 years.

The younger the patient, the more likely the individual will outlive the artificial knee and require surgery to repair or replace it. “Many of the problems after surgery are because of imbalance at the knee, or because the patient is doing exercises that could damage the implant,” Towfighian says.

The smart implant would transmit data from the sensor twice a day, via a cellphone link, to a physician. The doctor could then counsel the patient to avoid certain activities to reduce wear and tear on the implant, decreasing or delaying the need for a second surgery.

How the power source works

To power that sensor, Towfighian proposed using triboelectric energy harvesting. “Tribo” means friction. “Triboelectric” is another term for what you probably know as static electricity. If you’ve ever shuffled across a carpet and then suffered a shock when you touched a doorknob, you’ve done this type of energy harvesting yourself.

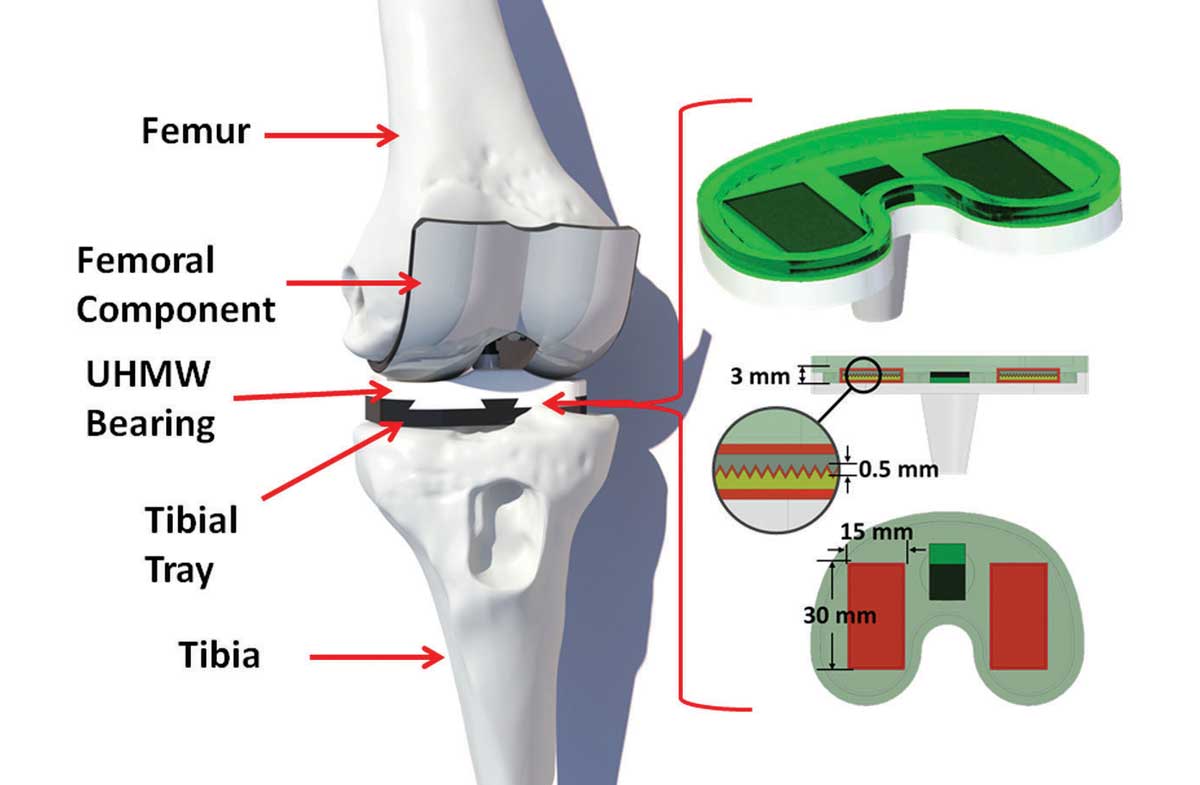

Towfighian’s triboelectric harvester includes two surfaces, each engraved with a micro sawtooth pattern. “When someone with a knee implant walks, these two surfaces touch,” she says. The ridges in the patterns rub together. “That friction gets converted to electricity, and that electricity can power the sensors.”

Wathiq Ibrahim, a postdoctoral researcher in Towfighian’s lab, conducted tests on the energy harvester, recording how much energy the device generated when installed in a piece of equipment that simulated a walking gait. Salman’s group designed an electronic circuit that can use the harvested power to produce data, which represents the load exerted on the implant. The team estimates that the small amount of current the harvester provides is enough to collect data several times a day. Towfighian and her colleagues described their results in a paper published in the journal Smart Materials and Structures in January 2019.

One expert who appreciates those findings is Darryl D’Lima, professor of molecular medicine at Scripps Research Lab in La Jolla, Calif. “Dr. Towfighian has found a clever way of using triboelectric energy harvesting,” he says.

A researcher who works to improve outcomes in orthopedic treatment, D’Lima did his own experiments with sensors for knee replacements more than 10 years ago. Those implants were not self-powered; the patients made regular visits to the research facility to power the sensors via an electromagnetic coil.

Besides helping to extend the lives of individual implants, data from the device developed at Binghamton could also help to improve the art of knee replacement, says John B. Medley, professor emeritus in the Department of Mechanical and Mechatronics Engineering at the University of Waterloo in Waterloo, Ont.

“If they can keep the sensor functional as the patient does things for many years, they’ll get enough feedback that it almost certainly will help them in some of their surgical techniques,” says Medley, whose research has focused largely on orthopedics. Data collected from many patients over time, thanks to the triboelectric harvester, could help surgeons learn to better balance an implant to reduce the risk of loosening and excessive wear, he says.

The allure of motion

The human knee is just the latest in a long line of mechanical systems that have fascinated Towfighian since her youth. “When I was in high school, I was interested in math and physics,” she says. “I liked things that moved. I liked to study how they moved — their speed and the properties of their motion.” From automobiles to space shuttles, they all piqued her curiosity.

Earning her BS in Iran, Towfighian worked on designing 3-meter-high butterfly valves for turbines used in hydraulic power plants in that country. She then decided to pursue her MS and PhD in Canada, focusing on micro-electrical mechanical systems (MEMS). “I was interested in very tiny things — fascinated that they can do such interesting things at a small scale,” she says.

Towfighian’s recent work with tiny devices includes an effort to build a more sensitive and accurate accelerometer, using MEMS sensors. Accelerometers, which measure motion, are used in all sorts of devices. The one in your cell phone, for example, may track your progress if you go for a run. A car uses an accelerometer to detect a crash and deploy the air bags.

With this new accelerometer, air bag systems might save more lives, Towfighian says. “It reduces the amount of processing that needs to be done, so it can act faster and be more reliable.”

In the future, Towfighian might pursue more biomedical uses for triboelectric energy harvesting. Given her team’s success with knee implants, it makes sense to try to apply the same mechanism to artificial hips, shoulders and other joints. “I was also thinking of the breathing motion,” she says. If a doctor needed to monitor a patient’s respiration, the in-and-out motion of those breaths could power a wearable sensor that takes the measurements.

The concept of a friction-driven sensor holds a great deal of promise for medicine, Medley says. “If this became routine, it might be something you would put in almost every implant.”