Need for speed: Formula racing team finds new direction as student club

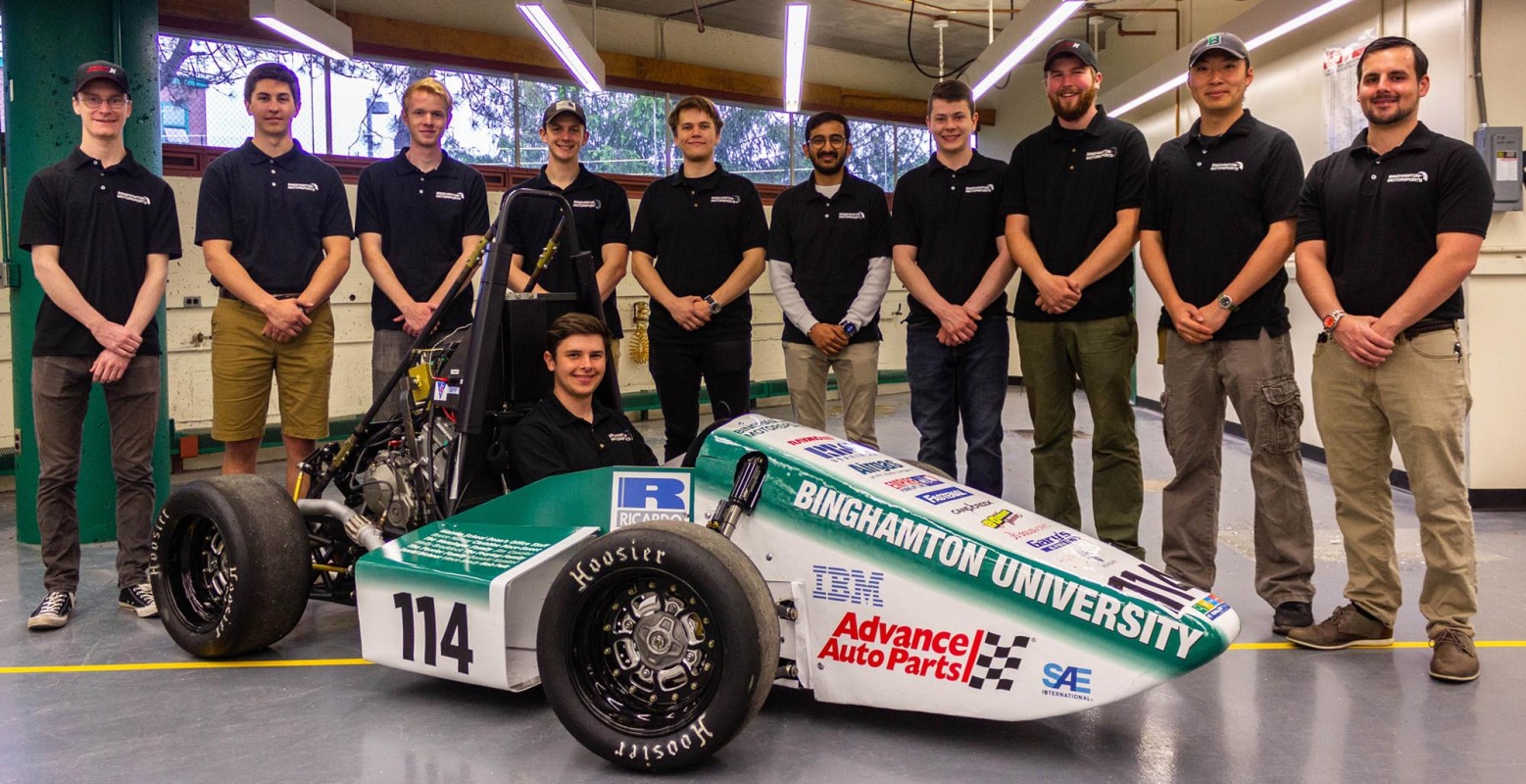

Binghamton Motorsports levels up at competitions

On an early Sunday afternoon on campus last October, the M-lot was closed to general traffic, but yellow cones sketched out a carefully plotted course.

Anyone who approached the lot first spotted the green trailer of Binghamton Motorsports, and from further away heard the throaty growl of a Formula vehicle bursting into a reverberating whine.

The course began with a straightaway leading into a slalom with breakneck twists, testing drivers’ abilities to handle intense forward and lateral motion. A mounted camera filmed each lap around the track, while a group of students stood watching, primed to quickly resolve any mechanical issues, and others sat on top of the trailer cracking jokes and taking pictures of it all.

After a particularly speedy run around the track, someone flashed Aaron Wojnicki a table of driver times that labeled the driver “freaking fast.” Except it didn’t say “freaking.”

Wojnicki, the project manager of Binghamton’s Formula Society of Automotive Engineers (FSAE) team, said that this driver testing is critical to their success, as the process reveals who is ready for the commitment, and who is not.

“The main goal today is to get a baseline for all of the people who want to be drivers, see if there’s anybody who comes out of the car and is shaking, or somebody who kills it on the course and can see themselves at competition,” he said.

The competition referred to is FSAE Michigan, an international event at the historic Michigan International Speedway. Since 1981, the annual competition has featured teams traveling from universities such as Michigan and Florida, and some from as far away as Germany. It also is attended by industry professionals from companies like General Motors and Ford.

New life as student club

Until 2018, the Formula team served as an assigned senior project — but in its first season as a student-run club, its members constructed a vehicle from scratch that impressed judges at the Michigan competition. Those grading the vehicle noted in particular its careful, meticulous construction that showed no indications of cramming for the deadline, such as poor welds or uncut zip-ties.

A major milestone for the first-year team was placing 43rd out of 130 teams in the category of technical inspection. The former project manager, Jacob Honsinger, put this achievement into perspective, saying that another team who placed third overall in the design competition failed the technical inspection.

“We take it for granted that we’re going to compete in the race, but competing in the race is a huge milestone,” Honsinger said. “That the car didn’t need any significant modifications to pass the technical inspection is huge.”

In its second year as a club, the Formula team is emphasizing documentation. Wojnicki explains that when the Formula car was limited to a senior project, students came in without the knowledge necessary to construct a vehicle, then left without documenting their valuable experiences for incoming students.

“By doing some documentation, even if it’s just a little bit, it gives younger people something to work off of and say, ‘This is where they were going with it, and this is where they went wrong,’” he said.

Matt Szymanski, chief engineer of the Formula team, finds the design and fabrication process easier in the team’s second year. Not only do team members have the car itself as a base, they also can incorporate suggestions from the competition’s design judges into their work.

To prevent an excessive workload when building the vehicle, Szymanski says that each subteam is limited to one major goal.

“Powertrain’s major thing is a custom oil pan. Suspension’s is new uprights and hubs. Frame’s is a new flat bottom,” he said. “We didn’t try to take on too much and have the project fail.”

One thing that the team cannot plan for is the unpredictability of competition. Last year, during the endurance competition (a long-distance race meant to test the durability of the car), the starter button broke, eliminating the team from the event.

“It shows how many things can go wrong,” Syzamanski said. “There are a million components just like that on this car. If one bolt comes loose or one wire comes disconnected, things like this can happen.

“The more testing you get on the car, the better. We had our chain tensioner break seven times in the first month of testing. If we didn’t have that time, it would have broken during competition and we would have been out. The starter was something we couldn’t see and couldn’t plan for.”

A better workspace

Speaking of the unexpected, the Formula team had to temporarily relocate its facilities during the fall semester because of ongoing renovations in the Engineering Building. Their stand-in office was a cramped room in the classroom wing, its dimensions almost comically small, with two whiteboards blanketed with figures and formulas. Additionally, a relatively small garage with all the necessities (such as a welding station) was set up for the team in the Fine Arts Building.

The team credits Dave Richner, shop technician and Formula team adviser, for arranging the necessary changes. A new garage and workspace are part of the Engineering Building’s new Fabrication Lab (nicknamed the “Fab Lab”).

“From a vehicle team standpoint, which I really care about, there’s going to be a garage door,” Richner said.

To test their car in the past without a garage door required team members to tip the car on end, fit it through a doorway and onto a loading dock, and then reverse the process to get the car back inside the garage when finished with testing.

“It’s huge,” Richner said. “They’re going to have their own booth with a welding area. It’s going to be really nice.”

Richner has supported student engineering projects at Binghamton University for 13 years and is excited by the development of the Formula team as a student-run club.

“We’ve got a team that is unbelievably intelligent, well-versed — they show themselves well,” he said. “They’re true engineers and true good people, through and through. They are putting a whole system together, that most people take years to build, in months. We are pumping out some bright engineers.”

Skills beyond Binghamton

Richner noted that alumni who were part of past Binghamton Motorsports projects have told him how fruitful their experiences were in the job-hunting process. At a recent competition at Michigan, an alumnus told Richner that General Motors brought him in for an interview for no reason other than that his résumé contained the experience of constructing a Formula vehicle.

“General Motors said, ‘That’s not saying you’re getting the job, but this experience got you an interview because we know that you’re an engineer who can design and build,’” he said. “That says an awful lot.”

Wojnicki had a similar experience. In the summer of 2019, he interned with Lockheed Martin Corp., an opportunity he credits to his Formula team experience.

“Going into the interview, this was the thing they asked the most questions about, what I could talk most about and what I was most passionate about,” he said. “I accepted a job offer from Lockheed, so I will be there starting after graduation.”

More important than these opportunities, to the members of the Formula team, is the pure passion they have for their work

“It’s all about the passion,” Wojnicki said. “Nobody is getting a grade on it, nobody is doing it for the money, it’s all people who are passionate about it and are willing to put the time in.”

What is most remarkable about the team, especially to Richner, is the inescapable sense that what they have accomplished at Binghamton is merely scratching the surface of future potential.

“This is the beginning,” Richner said. “I don’t know if I’m smiling enough, but what they’re building, they’re building to last. Every move they make is ensuring that when they walk out the door, the ground is laid so it’s not going to fall.

“They’re irreplaceable. I don’t want to see them leave.”