COVID-19: Watson School designs UV sterilization stations to aid healthcare workers

Setup from Biomedical Engineering Department shown to kill viruses

As the COVID-19 pandemic continues into its second month across the U.S., supplies of personal protective equipment (PPE) such as N95 masks and face shields continue to run low at many hospitals.

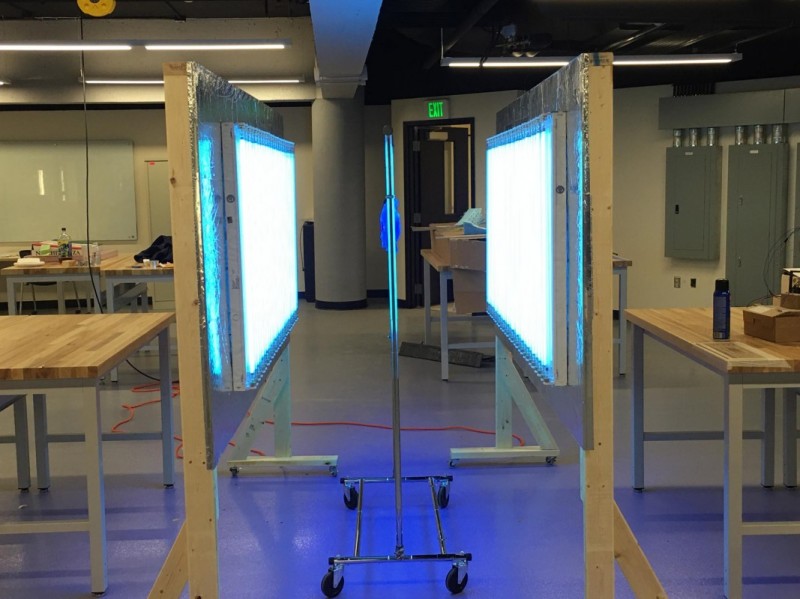

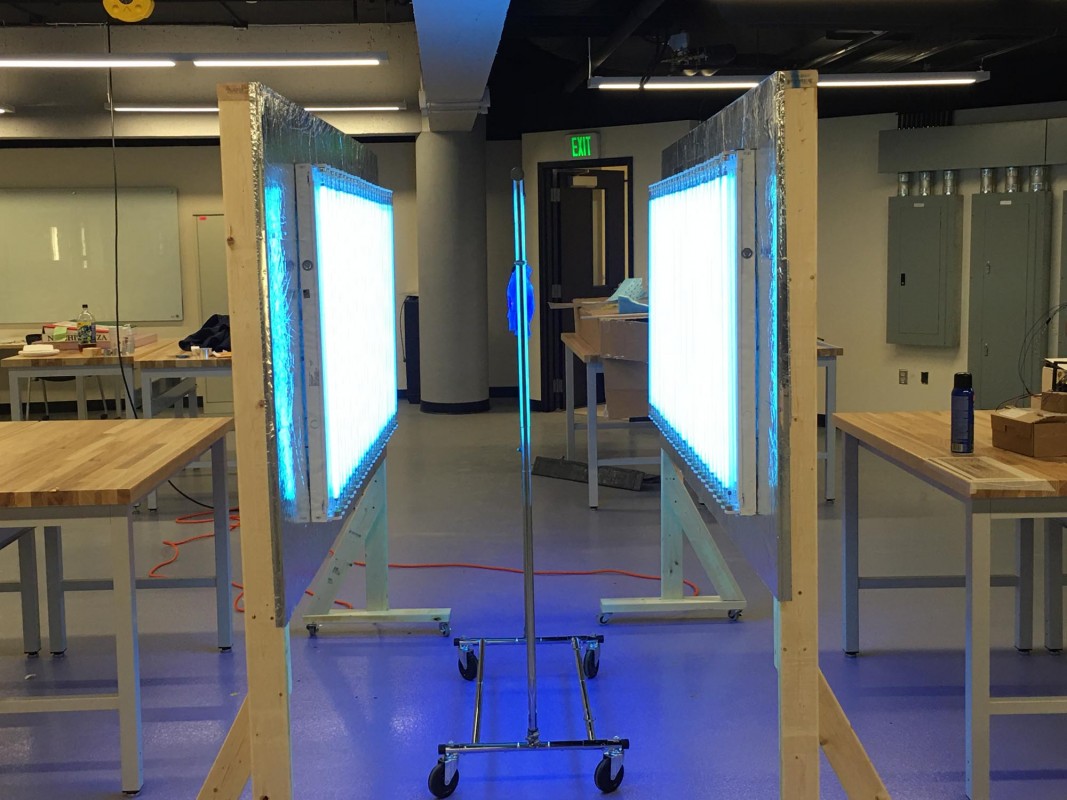

Researchers at Binghamton University’s Thomas J. Watson School of Engineering and Applied Science have addressed this problem by designing sterilization stations that use ultraviolet light to kill the coronavirus on any contaminated PPE.

The stations already are set up and in use at Binghamton-area hospitals through UHS and Lourdes, and the Department of Biomedical Engineering — which is organizing the project — has received inquiries from healthcare providers elsewhere in New York as well as Pennsylvania and the U.K.

Just plugging in a UV lightbulb and flipping it on is not enough. The stations feature large UV bulbs and foil to increase the amount of energy available to kill COVID-19 on any surface. The pieces can be purchased at hardware stores and assembled within three hours.

Professor Kaiming Ye, chair of the BME department, led the design project with help from BME colleagues Guy German (associate professor), Fake “Frank” Liu (assistant professor), Ying Wang (assistant professor) and others.

Ye said one reason that Watson’s sterilization stations are getting attention is that he and his collaborators have shown the technique to be effective: “We have a theory behind it. We looked at the data on SARS and other coronaviruses, and we built a computational model. We checked the literature and made sure that the dosage we use is correct and effective. We also did tests that validate the design.”

Testing directly with COVID-19 would be unfeasible given Binghamton’s current research capabilities — but thanks to a $7,500 seed grant from SUNY, Ye and the Watson team will test a “model microorganism” similar to the virus.

The Watson School built sterilization stations for UHS and Lourdes in the newly refurbished Fabrication Lab, but researchers also have shared the schematics with healthcare providers outside Binghamton University’s immediate area.

Because of quarantine rules about social distancing, the Watson team mainly has collaborated online to create the sterilization station.

“We can’t have in-person meetings, but scientists are adaptable in that way,” Ye said. “We can meet in virtual space, sketch the design, discuss the science and the data, argue about the calculations, and then everyone contributes to the solutions.”