The Nobel Prize: Building batteries at Binghamton

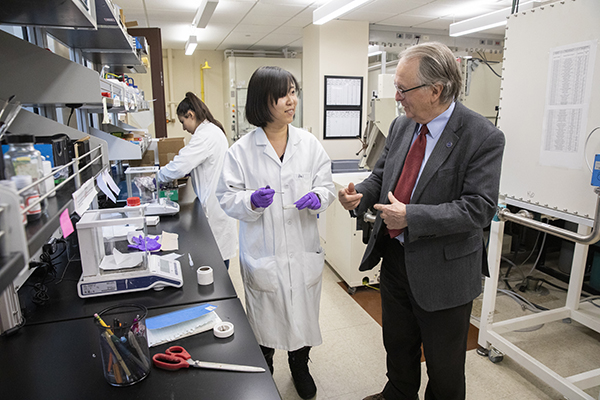

Whittingham's team includes doctoral students and postdoctoral fellows

What’s special about Binghamton’s approach to battery research?

Researchers working with M. Stanley Whittingham, funded by the NorthEast Center for Chemical Energy Storage (NECCES) and other projects, take a holistic and perhaps uniquely ambitious approach to making and testing batteries.

“We only work on things that can power a million cars,” Whittingham says. “There’s no point wasting your time with — how many elements are there? A hundred? Well, there’s about half a dozen of them where there’s enough of them in the Earth’s crust. That doesn’t mean we don’t put a pinch of something else in them, but those are the core materials.”

His team at Binghamton:

• Starts with powdered precursor materials, including lithium and other chemicals.

• Characterizes the materials, using X-ray and other techniques. Laboratory tools include a thermogravimetric analyzer, which measures the mass lost or gained during materials’ reactions at different temperatures. It can heat samples up to 1,000 degrees Celsius. The analysis helps researchers predict reaction temperatures for their experiments.

• Makes hundreds of coin cell batteries, each about the size of a quarter.

• Tests the batteries, subjecting them to a process that “cycles” them, charging them up and then running them down. (The cycler at NECCES, which boasts 120 channels, analyzes the electrochemical properties of coin cell batteries over periods ranging from a day to more than a year.)

• Selects the best formulations of those small batteries to be produced as “pouch cell” batteries, which are about 2 inches square and half an inch thick.

• Produces these “pouch cells” in a specialized dry room, similar to conditions at a small manufacturer.

• Tests the electrochemistry of the “pouch cells,” often at Brookhaven or Argonne national laboratories, with specialized X-rays to measure the structure.

Whittingham envisions an automated facility in nearby Endicott that would function at the level of a small-scale factory as the ideal next step for this research. “We could have manufacturers making real-sized cells for evaluation by potential customers,” he says.

NECCES, an Energy Frontier Research Center funded by the Department of Energy’s Office of Science and directed by Whittingham, unites an international team of scientists with an interest in improved battery technology.

His team at Binghamton, including seven doctoral students, several postdoctoral fellows, a couple of undergraduates and even one high school student, always has multiple ideas in the works.

“You’re always looking for better and different materials,” he says. “You never have one track. Whenever you get federal funding, you say we’re going to try A, B and C.”