Situational awareness can mean life or death, so researchers seek to measure it objectively

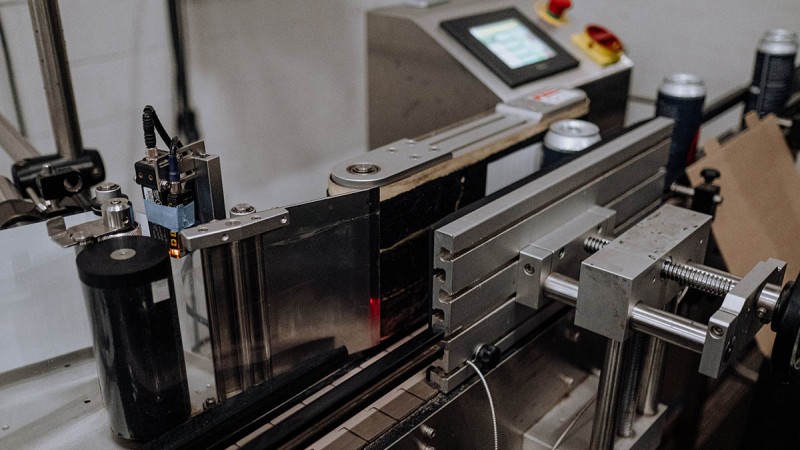

Assistant professor wants to make smart manufacturing and other related sectors safer

Situational awareness — the ability to perceive, understand and effectively respond to different variables in a safe, efficient way — is important in all walks of life, but especially those in high-pressure jobs where lives are on the line.

Military analysts and industrial engineers use the Situation Awareness Rating Technique (SART) to measure how “present” soldiers, air crews, nuclear power plant employees and factory workers are. Originally designed for pilots, SART uses 10 different dimensions to measure someone’s situational awareness, including complexity, concentration, familiarity and variability.

The system has its critics, among them Assistant Professor Chao “Amanda” Shi, a faculty member at Binghamton University’s Thomas J. Watson College of Engineering and Applied Science. As part of her research for the Department of Systems Science and Industrial Engineering, she wants to make smart manufacturing and other related sectors safer.

“If we don’t have a correct perception and an understanding of our environments, humans may make wrong decisions,” she said. “For instance, if an air crew wants to change the altitude of the aircraft, they need to look at the correct indicators. But sometimes the indicators for altitude and velocity are too similar. Crew members may misread them and make mistakes, causing a fatal accident.”

Shi’s research — a collaboration with Professor Ling Rothrock from Penn State University — aims to measure situational awareness more objectively through eye-tracking technology. Shi and Rothrock concluded that at least four of the 10 dimensions that SART monitors are skewed by participants’ perceptions.

“In subjective situational awareness environments, many of the questions are asked in such a way that they’re actually measuring some other metric, like workload,” she said.

Shi and Rothrock’s experiments put participants (mainly college students) into simulated smart-manufacturing scenarios where they needed to finish a task on a computer as quickly and accurately as possible while dealing with abnormal events. If a gauge fell above or below a normal level, they were told to react.

“It’s preferable to run cognitive experiments with people who are working in industry, but it’s very difficult to find them when we’re in the university environment,” Shi said.

When Shi and Rothrock analyzed the data they collected, they found that the subjects’ perceptions influenced the outcomes. Factoring in the more objective eye-tracking results led to different conclusions.

Further research is ongoing through Shi’s Human Cognitive and Visual Behavior Lab. Because being a pilot is different than working in manufacturing and other jobs, she would like to develop individualized SART measures for each field.

“When you’re in the industrial engineering, there a lot of technologies we apply, but sometimes people overlook the human part,” she said. “We want to make technology work for people, but in some instances, we’re trying to adapt ourselves to the technology. If we can measure human situation awareness accurately in different work environments, we will be able to know more about human internal states and therefore improve the system design and safety.”