Helping hand: SPIR aids small companies by solving tech problems

Since 1994, New York state has helped fund partnerships that seek solutions to thorny technological problems

In today’s rapidly changing business environment, companies must utilize the latest advances in technology to succeed. Keeping up with these developments, though, can be costly.

That’s where the Strategic Partnership for Industrial Resurgence (SPIR) can lend a hand. Since 1994, New York state has helped fund partnerships at four State University of New York (SUNY) engineering programs — Binghamton, Buffalo, Albany and Stony Brook — that seek solutions to thorny technological problems.

Watson College’s SPIR program assists small and midsize businesses through projects that bring together students, faculty and industry personnel. In addition to problem-solving services, SPIR assists entrepreneurs in developing their concepts into demonstrations or prototypes for attracting venture capital or licensing agreements.

Started by Gov. Mario Cuomo and supported by Assemblywoman Donna Lupardo since her election to the state Legislature in 2004, SPIR has helped to create or retain about 2,500 jobs in the Binghamton region, generating $90 million a year. Hundreds of students also have benefitted from applying their skills to real-world problems.

“The staying power of SPIR and the fact that it remains a viable program after 30 years is a testament to the positive effect it has had on our regional economy, faculty and students,” says Michael Testani, MS ’02, Watson College’s senior director of outreach and engagement who oversees the SPIR program.

“SPIR is a true ‘win-win’ scenario where small and startup businesses gain access to the outstanding assets of a premier research and academic institution. The University also benefits by providing valuable, real-world technical challenges that expand the perspectives of our faculty and students.”

Companies and entrepreneurs apply to the SPIR program with their proposals, and if accepted, a cost-sharing plan pays for the labor. One graduate student gets a tuition scholarship and stipend, and the faculty member gets a stipend for serving as an advisor.

About a dozen companies work with Watson College on more than 20 projects during an academic year, primarily in hardware and software product development, information technology services and manufacturing support. Among the projects for the 2023–24 academic year were the development and testing of energy storage systems, evaluating systems for water desalination and analyzing additive manufacturing technology.

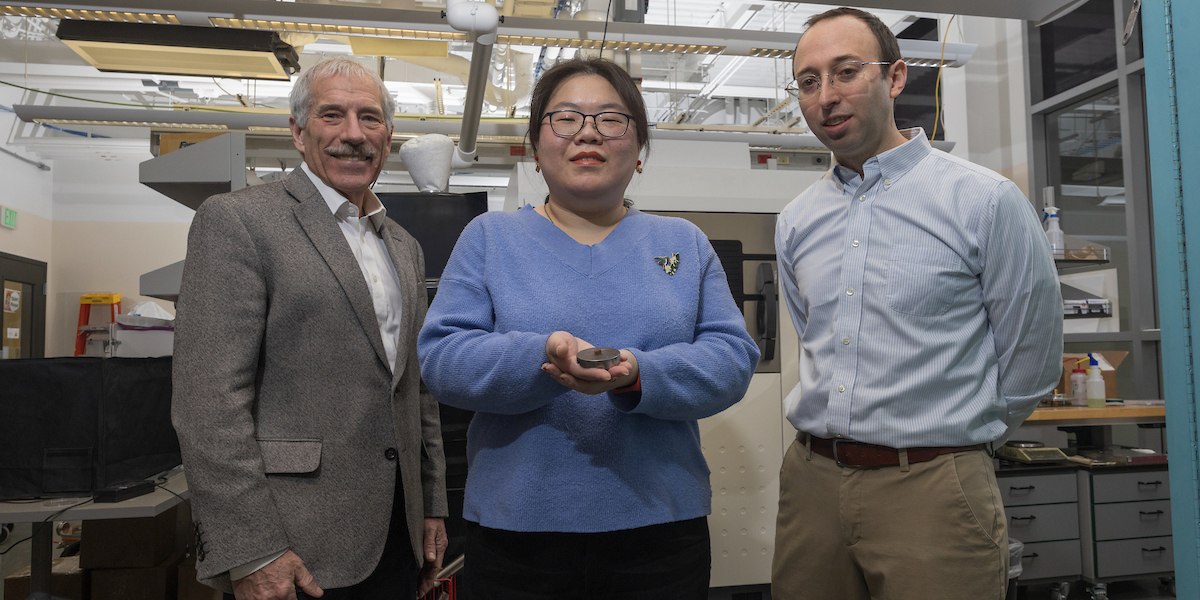

That last project is with ChromaNanoTech, founded in 2014 by Binghamton University chemistry professors William Bernier, PhD ’79, and Wayne Jones to implement patented technology they developed. It operates at the Koffman Southern Tier Incubator under the START-UP NY program, which offers tax incentives to new businesses that partner with a state college or university.

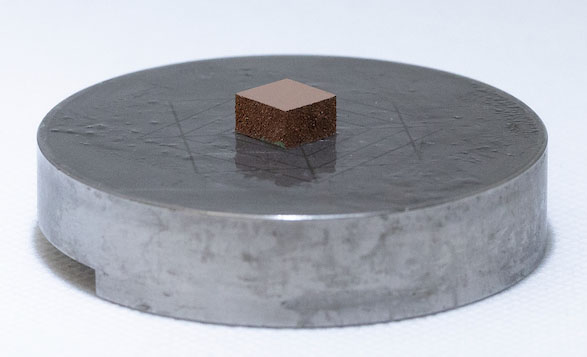

ChromaNanoTech has partnered with SPIR for the last few years to perfect two main products.One is a method of printing barcodes directly onto metal that would withstand weathering, and the other would improve 3D printing of pure copper.

“We have a lot of companies that are interested in both of these technologies, and SPIR has done some of the fundamental work to help us develop them,” says Bernier, who serves as ChromaNanoTech’s CEO.

Copper is a key component for circuit boards and heat sinks that keep our electronics running smoothly, but the properties that are most useful to engineers — high electrical conductivity, high thermal conductivity and malleability among them — also make it a difficult metal for additive manufacturing.

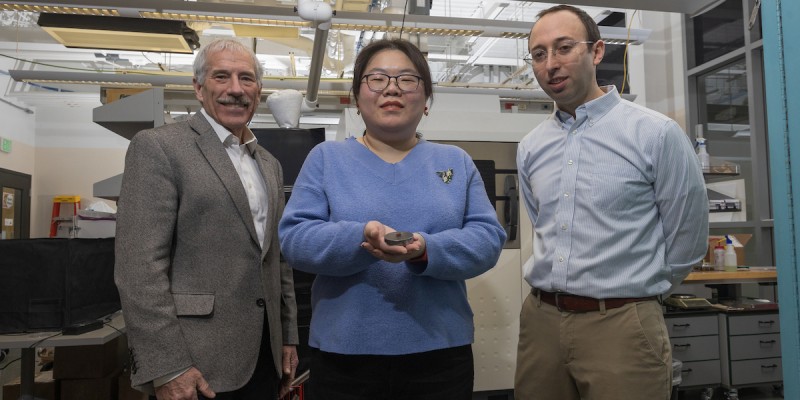

The copper project came from an idea that Bernier and Associate Professor Scott Schiffres, a faculty member in the Department of Mechanical Engineering, discussed several years ago. Now, Schiffres is guiding the possibilities through SPIR.

“Hopefully we’re going to have a patent, a paper and a product, which is not so common for academic research,” he says. “It’s very nice to have that trajectory.”

Once a copper piece has been printed, it needs to undergo testing to judge its quality. SPIR allows small companies like ChromaNanoTech to access Binghamton’s superior lab spaces for the characterization process.

Zechen Zhang, Schiffres’ PhD student, uses the various equipment at the Analytical & Diagnostics Laboratory at the Innovative Technologies Complex on campus. An initiative of the Small Scale Systems Integration and Packaging Center (S3IP), a New York State Center of Excellence, the ADL offers more than 50 devices for advanced materials analysis, including optical microscopy, electron microscopy, atomic force microscopy, acoustic imaging and 3D X-ray imaging.

“This collaboration is very good for my future career,” Zhang says. “As a PhD student, I get to see how industry works and how products are invented. We received valuable advice from both industry-facing and research-focused perspectives.”