Background

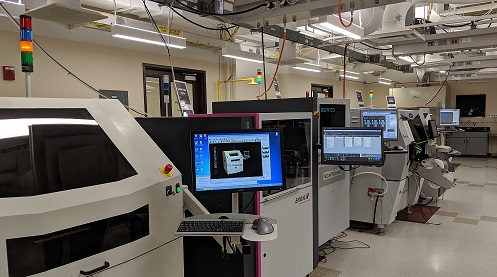

Our Smart Electronics Manufacturing Laboratory (SEMLab) serves to improve the assembly process in electronics manufacturing using Artificial Intelligence integration.

With support and initial funding from Koh Young Technology Inc., based in Seoul, Korea, the SEMLab was established in 2016.

Our 6 collaborative partners have provided valuable equipment to create this impressive, one of a kind smart factory.

The projected value of SEML is 205.24 Billion (USD) by 2022, with a growth rate of 9.3% per year.

A closer look

Technical Perspective

The objective of the SEMLab is to develop smart electronics manufacturing solutions using data science (DS) and artificial intelligence (AI) principles to assemble sophisticated electronics components, and surface mount assembly (SMA; module assembled with SMT) line which consists of a set of sequential procedures/equipment; stencil printing process (SPP), mounting, and solder reflow.

Our Smart Assembly

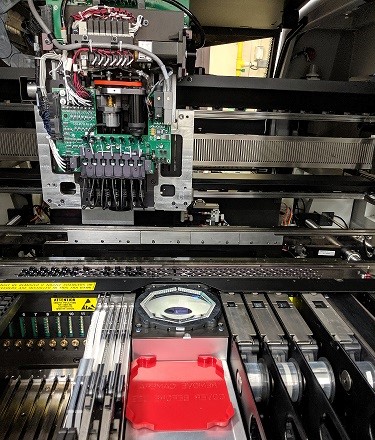

We focus on advanced robotic solutions to assist SMA line and revolutionize electronics manufacturing process with improved yield and productivity.

With automatic optimization, real-time intelligence techniques, and the implementation of advanced analytical approaches to large data collected from the equipment in SMT, the smart electronic manufacturing systems can optimize current SMA line operations with:

- Fewer defects

- High productivity

- Increased reliability

- Cost efficient results

How SEMLab can help your product development

If you are looking for a cost-effective way to ensure a reliable product, we are confident that our SEMLab will check off your list of required capabilities that will successfully assemble your prototype.

PCB Design Reviews:

- DFM (Design for Manufacturablilty) using advanced software tool, PollEx.

- SI (Signal Integrity) Validation.

NPI (New Product Introductory):

- Build prototypes utilizing full SMT assembly line.

- Feedback optimum process settings in SMT manufacturing requirements.

- Evaluate SMT Manufacturing Process.

Material Evaluation:

- Analyze and evaluate provided materials such as Solder-Paste, Stencils, Bare- boards, Components, and more.

Whether it is a quick phone call or an inhouse visit, we are ready to offer you a tour, answer your questions, and setup a contract on the basis of your goals, budget and expected turn around time.

Contact our interface specialist, Ron Kuracina, at kuracina@binghamton.edu for quotes or answers to your queries.

Principal lab engineers and researchers:

Sang Won Yoon - Associate professor of systems science and industrial engineering

Daehan Won - Assistant professor of system science and industrial engineering

Lab Location:

B500